Subscribe to Pittwire Today

Get the most interesting and important stories from the University of Pittsburgh.Playing air guitar just got sweeter for Dylan Dzikowski.

Dzikowski turns up AC/DC from the computer on his wheelchair, which includes a speech generation device, as Alyssa Boccardi, an occupation therapy PhD student at Duquesne University, hands him a new bright blue guitar pick. Dzikowski taps his feet and strikes his air guitar with pick in hand.

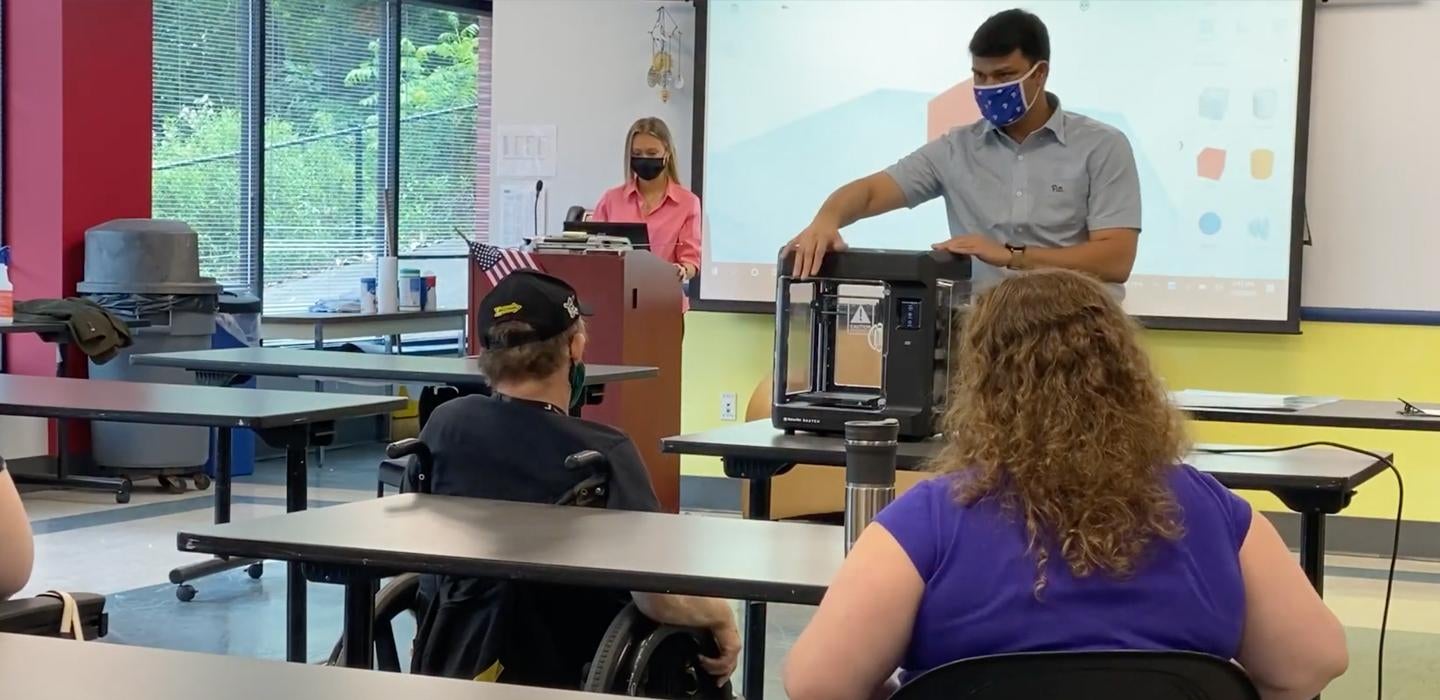

Boccardi made the pick for Dzikowski from a 3-D printer that is part of a new makerspace at Community Living And Support Services or CLASS in Pittsburgh’s Swissvale borough, east of the city. CLASS is a nonprofit organization that offers programs and services for people with disabilities to assist them in playing an active role in the community.

Anand Mhatre, an assistant professor in Pitt’s Department of Rehabilitation Science and Technology at the School of Health and Rehabilitation Sciences, just finished teaching a lesson with Boccardi on 3-D printing. Mhatre’s research focuses on data-driven development and usability testing and technology transfer of assistive devices.

For Mhatre, teaching a community class is an experiment of sorts. Through it, Mhatre hopes to create an ecosystem with staff and students at CLASS so they can build and create a variety assistive technologies.

Mhatre, who teaches graduate courses in health sciences and bioengineering at the University, taught several mini-lessons at CLASS, including this one where the students learned how to take their sketches from the previous session and build tiny versions of their objects using the 3-D printer. For the demonstration, Mhatre uses a model of a tiny house.

“If you’ve seen an ice cream vending machine, ice cream comes out when you pull the lever. It’s similar,” Mhatre explains.

Students gather around Mhatre as he describes the additive manufacturing process and starts the printer.

“Do you think this is easy to make?” Mhatre asks.

Dzikowski replies “yes” through this speech generation device and a few laughs erupt from the class.

“Anyone want to take it out?” Mhatre continues.

“Is it cooled down enough?” asks student Denis Barbour.

“Aha,” student Denis Barbour exclaims as he opens the door to the 3-D printer, removes the tiny house, and holds it in his hand.

“I think this is just a start for us,” says Mhatre. “I worked with students and staff we have produced several assistive technologies, small and big.” “We wanted to empower the class community so that you can make technologies that can be used in daily life.”

For Barbour, daily life includes pushing his chair without a place to put his coffee or his water bottle.

After class, Barbour and Mhatre discuss how they might make a cup holder for his wheelchair using the 3-D printing machine.

“We can have something on the chair right there,” Mhatre says pointing to a spot on Barbour’s wheelchair.

Barbour and Mhatre discuss how any cup holder has to be built so that it can withstand tremors in Barbour’s hands.

“Let’s make it,” says Mhatre.

— Elizabeth Raffaele