RESEARCH HIGHLIGHTS

Topology Optimization of AM Cellular Structures

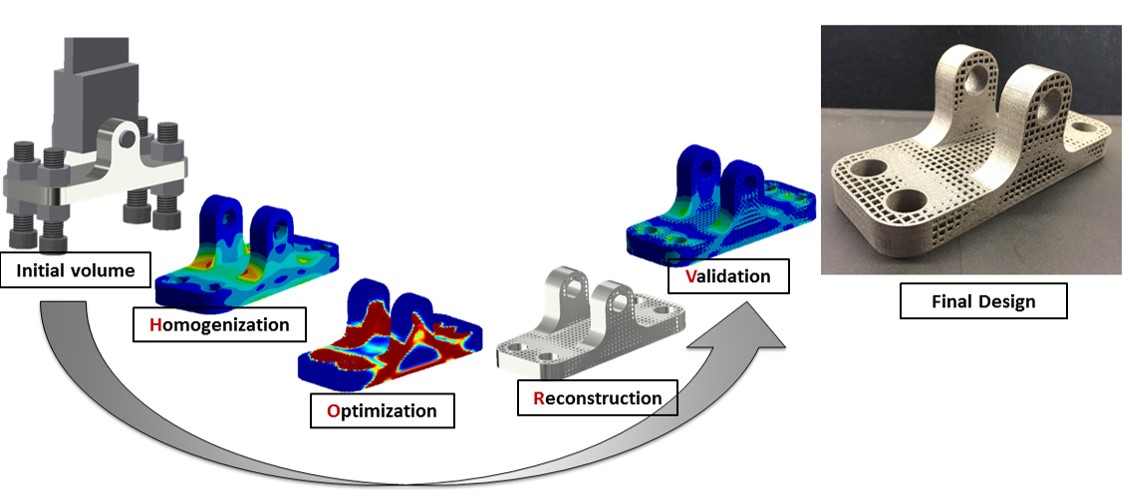

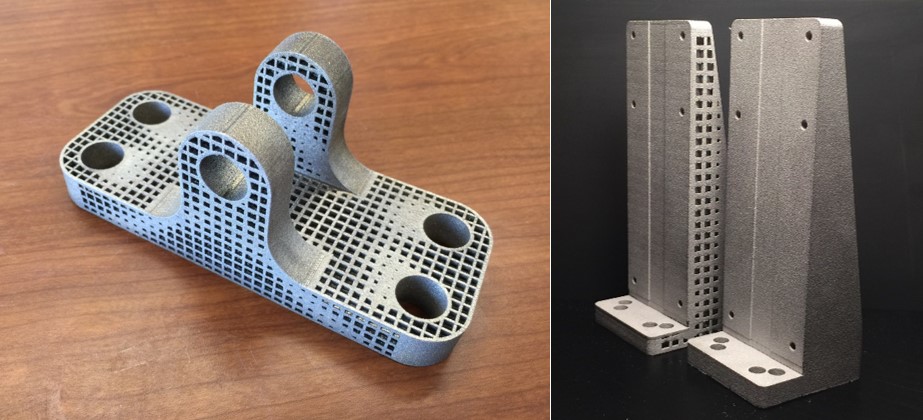

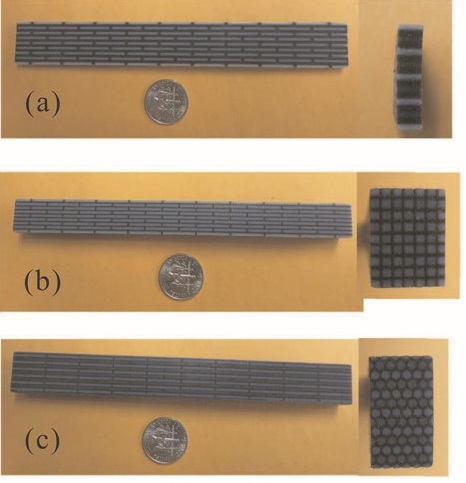

Cellular structures can be employed effectively in lightweight structural design to overcome some of the manufacturing limitations existing in additive manufacturing (AM). For this purpose, a homogenization-based topology optimization method is proposed to optimize variable-density cellular structures efficiently. First, homogenization is performed to capture the effective mechanical properties of cellular structures through the scaling law as a function of relative density. Second, the scaling law is employed directly in the topology optimization algorithm to compute the optimal density distribution for the part being optimized. Third, a new technique is presented to reconstruct the CAD model of the optimal variable-density cellular structure. The proposed method is validated by comparing the results obtained through homogenized model, full scale simulation, and experimentally testing the optimized parts after being additive manufactured. The test examples demonstrate that the proposed homogenization-based method is efficient, accurate, and is able to produce manufacturable designs.

[1] L. Cheng, P. Zhang, E. Biyikli, J. Bai, J. Robbins, M. Lynch, E. Butcher, and A. C. To, “Efficient design optimization of variable-density cellular structures for additive manufacturing: Theory and experimental validation,” Rapid Prototyping Journal, 2016. (accepted)

[2] P. Zhang, J. Toman, Y. Yu, E. Biyikli, M. Kirca, M. Chmielus, and A. C. To, “Efficient design-optimization of variable-density hexagonal cellular structure by additive manufacturing: Theory and validation," ASME Journal of Manufacturing Science and Engineering, vol. 137, 021004, 2015.

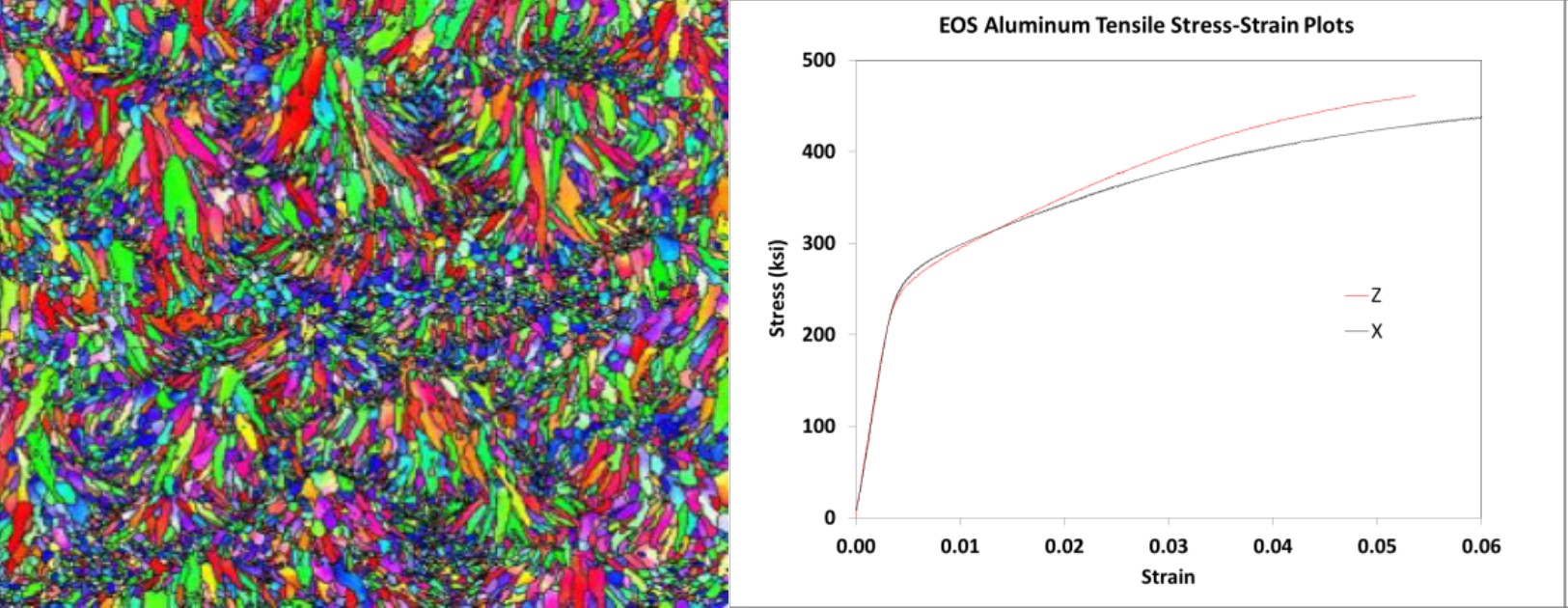

Modeling Microstructure and Property of AM Metals

Advances in additive manufacturing (AM) technology have made it possible to manufacture complex-shaped metal components strong enough for real engineering applications. To date, the process-microstructure-property relationship for AM metals has mostly been investigated experimentally, which is expensive and time-consuming since the parameter space is quite large. The lack of a reliable theoretical model for predicting such relationship makes it difficult to design AM components. The goal of this research is to establish a theoretical model that is capable of predicting the microstructure (texture, grain size, shape and subgrain features length scale) and mechanical properties (strength and anisotropy) of an AM metal based on the input process parameters (beam power, scan speed, preheat, and scanning strategy).

[1] J. Liu and A. C. To, "Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting,” (submitted)

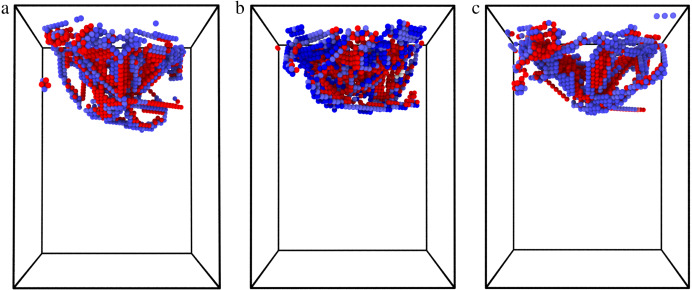

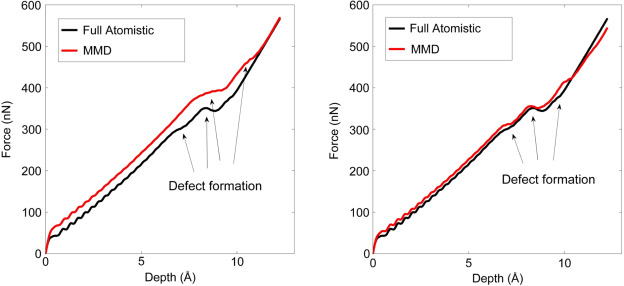

Multiresolution Molecular Mechanics

In the last five years, we have been developing a new energy-based concurrent atomistic/continuum framework called the Mutiresolution Molecular Mechanics (MMM) that includes formulation for both the statics (MMS) and dynamics (MMD) methods. By introducing a novel energy sampling framework, MMM aims at accurately and efficiently approximating the atomic energy of the system at different resolutions without the cumbersome interfacial treatment in existing methods. The key features of the MMM method are: (1) consistency with the atomistics framework, (2) consistency with the order of shape functions introduced, and (3) flexibility in energy approximation with respect to accuracy and efficiency. Under the energy sampling framework, several sampling schemes have been devised and tested for interface compatibility, and compared to existing methods. The proposed MMM method demonstrates very good accuracy in solving many different problems such as crack propagation and surface relaxation problems when compared to full molecular statics.

[1] E. Biyikli and A. C. To, “Multiresolution molecular mechanics: adaptive analysis,” Computer Methods in Applied Mechanics and Engineering, vol. 305, 682-702, 2016.

[2] Q. Yang and A. C. To, "Multiresolution molecular mechanics: a unified and consistent framework for general finite element shape functions," Computer Methods in Applied Mechanics and Engineering, vol. 283, 384-418, 2015.

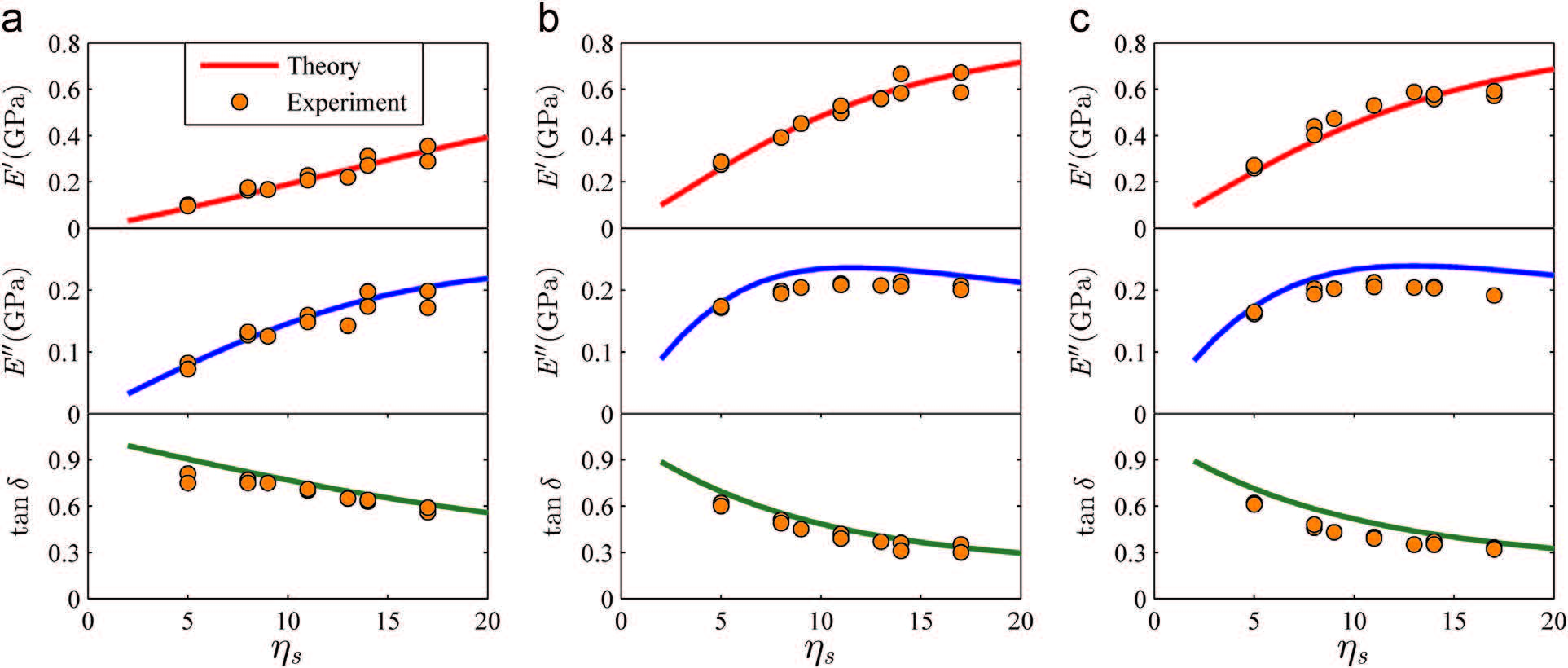

Mechanics of Bioinspired and Phononic Structures

We believe nature optimizes certain mechanical properties of biological materials by designing microstructure. Recently, we have discovered interesting mechanical behaviors in hierarchical structure found in many biocomposites. For example, hierarchical structure can enhance wave filtering and damping figure of merits significantly.

[1] P. Zhang, M. Heyne, and, A. C. To, “Biomimetic staggered composites with highly enhanced energy dissipation: modeling, 3D printing, and testing” Journal of Mechanics and Physics of Solids, vol. 83, 285-300, 2015

[2] P. Zhang and A. C. To, "Broadband wave filtering of bioinspired hierarchical phononic crystal," Applied Physics Letters, vol. 102, 121910, 2013.